Address

No.3 Chengcai Road, Leliu Town, Shunde District, Foshan City, Guangdong, China 528322

Address

No.3 Chengcai Road, Leliu Town, Shunde District, Foshan City, Guangdong, China 528322

Select a reliable China bed manufacturer by checking certifications, quality, export experience, and custom options to match your business needs.

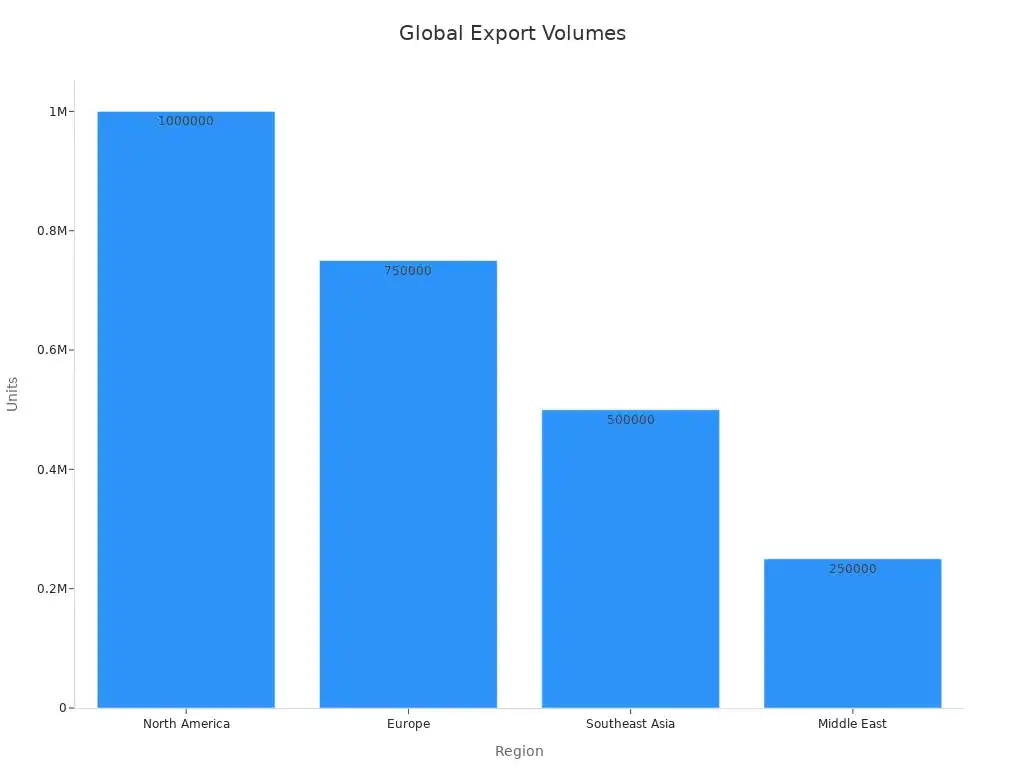

You need to look for trustworthy supplier choices when picking a China bed manufacturer. Many people want beds from China, and this number keeps going up. In 2023, China sent out 2.5 million beds to other countries. These beds were worth US$3.5 billion. The table below shows how many beds went to each area:

Metric | Value | Year-on-Year Growth | Notes |

|---|---|---|---|

Total Export Volume | 2.5 million units | +15% | Data for 2023 |

Total Export Value | US$3.5 billion | +18% | Data for 2023 |

North America Export Volume | 1 million units | N/A | 40% of total exports; electric and ICU beds |

Europe Export Volume | 750,000 units | N/A | 30% of total exports; multifunctional beds |

Southeast Asia Export Volume | 500,000 units | N/A | 20% of total exports; cost-effective beds |

Middle East Export Volume | 250,000 units | N/A | 10% of total exports; high-end beds |

You should think about the most important things, like credentials, product quality, and if the supplier is reliable. Having a good relationship with your supplier will help you get what you need. It will also help you not make expensive mistakes. Always check each supplier well to make sure they fit what you want.

First, know what kind of bed you want. Think about the bed type, materials, how many you need, and your budget. Do this before you talk to suppliers.

Always look for certifications like BSCI, FSC, ISO 9001, and CE. These show the manufacturer makes good and safe products.

You can use online websites, trade shows, or ask people you know to find Chinese bed manufacturers. Compare a few before you choose.

Pick suppliers who have lots of experience and many products. Make sure they have the right certificates. Check if they reply fast and read customer reviews.

Ask for samples and photos of the beds. This helps you check the quality before you buy a lot.

Make sure the manufacturer checks quality well. You can also use another company to check the beds for you. This helps stop problems and keeps beds safe.

Look at how big the factory is and how much it can make. Check how long it takes to finish orders. Make sure they can handle your needs.

Always talk clearly and politely with suppliers. Discuss the deal carefully. This helps you trust each other and work well together.

First, think about what kind of bed you want. Chinese manufacturers make many types of beds. You can pick single beds, double beds, bunk beds, or adjustable beds. Some suppliers also make hospital beds, children’s beds, and luxury beds for hotels. Each bed type is made for a special use. Bunk beds are good for hostels or kids’ rooms. Adjustable beds are best for hospitals or elderly care. If you know the bed type you need, it is easier to search. You can also talk clearly with suppliers.

Tip: Write down the bed types you want before you talk to any manufacturer. This will help you save time and stop confusion later.

The bed frame material changes the quality and price. Beds can be made from solid wood, metal, MDF, or mixed materials. Solid wood beds last longer and look nice, but they cost more. Metal beds are strong and simple to clean. Many schools and hospitals use metal beds. MDF beds are cheaper, but they may not last as long. Some manufacturers use eco-friendly materials. These can help you meet green rules in your market.

Solid wood: Strong, classic style, costs more.

Metal: Tough, easy to clean, modern look.

MDF: Cheap, light, not as strong.

Eco-friendly options: Good for green goals.

Pick the material that fits your needs and customers. If you sell to hotels, solid wood or metal is a good choice. For student dorms, MDF or metal may work better.

How many beds you order and your budget are important. Most suppliers have a Minimum Order Quantity (MOQ). This number is set by their costs and profits. If you want fewer beds than the MOQ, you can try to make a deal. Some suppliers let you order less if you pay more. You can also split your order into smaller groups to help with your budget and meet the MOQ.

Suppliers set MOQs based on how many beds you order and their profits.

You can ask for smaller orders by paying more or promising bigger orders later.

Splitting your order helps you control costs and meet what the supplier wants.

Using fewer materials and less custom work can lower the MOQ.

Chinese manufacturers like big orders because they make many beds at once. But if you talk clearly and are polite, you may find a good deal. Always talk about payment rules early. Many suppliers want a deposit first. You pay the rest after the beds are sent. If you build trust, you might get better payment rules next time.

Note: If you know your quantity and budget before you start, you can make better deals and avoid problems when you sign a contract.

When you pick a Chinese bed manufacturer, always check their certifications. Certifications prove the factory follows important rules. These rules make sure beds are safe and strong. They also show the beds are made fairly. If you want to sell beds in the UK or Europe, you must follow strict laws. Certifications help you show this to your customers and partners.

Here are some main certifications you should know about:

Certification | What It Means | Why It Matters |

|---|---|---|

BSCI | Business Social Compliance Initiative | Shows the factory treats workers fairly and follows good labour rules. |

FSC | Forest Stewardship Council | Proves the wood comes from forests that people manage well and protect. |

ISO 9001 | International Quality Management Standard | Means the factory has strong systems to keep quality high. |

ISO 14001 | Environmental Management Standard | Shows the factory works to protect the environment. |

CE Mark | European Conformity | Needed if you sell beds in Europe. Proves the beds meet EU safety rules. |

Tip: Always ask the supplier for copies of their certificates. Check the dates and make sure they are still valid.

Do not trust a supplier who cannot show real certificates. Some factories might say they have them, but they do not. You can check the certificate number on the official website. For example, you can check FSC numbers on the FSC website. This step helps you avoid fake certificates.

If you want to sell beds to schools, hospitals, or hotels, you may need extra certificates. Some buyers want fire safety certificates or proof the beds do not use harmful chemicals. You should ask your customers what they need before you order.

Certifications help you build trust with your buyers. When you show real certificates, buyers know you care about quality and safety. This can help you get more orders and better prices.

Make a list of the certifications you need before you talk to any manufacturer. This list will help you ask the right questions and choose the best supplier for your business. If you are not sure which certificates you need, you can ask a local trade group or check the rules in your country.

Remember, certifications are not just pieces of paper. They show the factory works hard to meet high standards. This gives you peace of mind and helps your business grow with confidence.

You can start your search for a china bed manufacturer by using online platforms. Many buyers use b2b platforms like alibaba to find suppliers. These websites let you see thousands of factories in one place. You can filter results by location, product type, or certification. This makes sourcing much easier and faster.

When you use these platforms, always check the supplier’s profile. Look for business licences, company history, and customer reviews. Many platforms show if a supplier is a verified manufacturer. You should also use the chat or message tools to ask questions. Ask about their experience, minimum order quantity, and delivery times.

Tip: Always compare at least three suppliers before you decide. This helps you find the best price and quality.

You can also meet a china bed manufacturer face-to-face at trade shows such as ciff. These events happen in big cities like Guangzhou and Shanghai. At a trade show, you can see and touch the beds. You can talk to the supplier directly and ask about their products.

Trade shows help you check the quality of beds before you order. You can also see new designs and trends. Many suppliers show their best products at these events. You can collect catalogues, business cards, and samples. This makes sourcing more personal and gives you more trust in the supplier.

Note: Plan your visit early. Make a list of suppliers you want to meet. This saves time and helps you focus on your needs.

You can also use referrals to find a good china bed manufacturer. Ask friends, business partners, or industry groups if they know a trusted supplier. Many buyers find the best suppliers through word of mouth.

A referral gives you extra confidence. If someone you trust had a good experience, you are more likely to get good service too. You can also ask the supplier for references from other customers. This helps you check if they deliver on time and keep their promises.

Make a list of all referrals you get.

Contact each supplier and ask about their products.

Check if they match your needs before you move forward.

Sourcing the right supplier takes time, but these steps help you find a partner you can trust.

Once you have a list of possible suppliers, you need to make it shorter. This helps you look at only the best choices. It also saves you time in the next steps. Use clear rules to compare each china bed manufacturer. Good shortlisting makes your search easier and helps you avoid problems later.

Start by checking what you found on online sites, at trade shows, and from referrals. Look at each supplier’s business details. Check how long they have worked, what beds they make, and if they sell to other countries. Reliable suppliers have worked for many years and have clear records. You can use a table to compare important facts:

Supplier Name | Years in Business | Main Products | Export Markets | Certifications | MOQ |

|---|---|---|---|---|---|

Supplier A | 10 | Metal Beds | UK, Europe | ISO 9001, FSC | 100 |

Supplier B | 5 | Wooden Beds | Europe, Asia | BSCI, CE | 50 |

Supplier C | 8 | Bunk Beds | UK, Middle East | ISO 9001 | 200 |

Check if the china bed manufacturer has the right certificates for your country. Ask for copies and check if they are real. If a supplier cannot show real certificates, take them off your list.

Next, see how they talk with you. A good supplier answers fast and gives clear replies. If they take too long or do not answer well, you may have trouble later. Good replies show they care about your business.

Ask for reviews or names of other buyers. You can talk to these buyers to learn about their experience. If a supplier has many good reviews, you can trust them more.

Here is a simple checklist to help you choose suppliers:

At least 3–5 years in business

Main products match what you need

Has sold to your country before

Has real certificates for your market

Answers quickly and clearly

Has good reviews from other buyers

Minimum order quantity (MOQ) is okay for you

Tip: Keep your list to 3–5 suppliers. This is easy to handle and lets you compare offers well.

Shortlisting helps you stay away from bad companies. You can focus on the best ones and get ready for the next steps, like asking for samples or visiting factories. Careful shortlisting is very important for finding the right supplier in China.

When you want to buy beds from China, you must pick reliable chinese bed frame manufacturers. You need to be sure the company can make good beds and meet your needs. This part will show you how to check if a manufacturer is honest and has lots of experience.

First, check if the manufacturer is a real company. Many people use online sites to find suppliers, but not all are real. Look for the business info section on the website. Here, you can see the company’s registration, how long they have worked, and what beds they make.

A good bed factory will have a clear past and good reviews. You can:

Check the supplier’s history and see how long they make beds.

Read what other buyers say about them.

Ask for stories or examples of old orders.

Talk to their customers to ask about the beds and service.

See if the company can make lots of beds as you grow.

Look at credit reports and see if the company is strong with money.

Test if the company answers your questions fast and clearly.

Always sign a contract to keep yourself safe.

Websites like Volza show how often a company ships beds and where they send them. This helps you see if the supplier is good and avoid problems.

Tip: Always look at a few companies before you choose. A good chinese bed frame manufacturer will share their business info and answer your questions.

Certifications prove a manufacturer follows rules for quality, safety, and fair work. You should always ask for copies of important certificates. The most common ones for bed factories are BSCI, FSC, and ISO 9001.

Certification | What It Proves | Why It Matters |

|---|---|---|

BSCI | Good labour practices | Workers are treated fairly |

FSC | Responsible wood sourcing | Wood comes from well-managed forests |

ISO 9001 | Quality management | Products meet high standards |

A good bed factory will have new certificates. Check the dates and make sure they are real. You can check FSC numbers on the FSC website. If you want to sell beds in the UK or EU, you may also need CE marking. This shows the beds are safe for Europe.

Some buyers need extra certificates, like fire safety or proof the beds are not toxic. Ask your customers what they need before you order. Good chinese bed frame manufacturers will help you get the right papers.

Note: Never trust a supplier who cannot show real certificates. This means the company may not be safe to use.

Export experience is very important when you pick a manufacturer. You want a company that knows how to send beds to your country and understands your rules. You can check export experience in many ways:

Look at the company’s export records on trade sites. See if they have sent beds to the UK or EU before.

Ask for a list of countries they send beds to and how many times.

Ask for names of buyers in your area.

Look at their catalogues and see if they have beds that fit UK or EU styles.

Researchers use surveys to learn about new ideas and export habits. They check how much a company tries new things and how often they export. Companies that try new ideas often do better with exports. You can ask the manufacturer about new beds and changes. This shows if they keep up with the market.

You should also think about where the company is in China. Some places have more export experience. Factories in these places may ship faster and have better supply chains.

Tip: Good chinese bed frame manufacturers will show their export history and proof of old shipments. This helps you trust them and avoid problems with customs.

If you follow these steps, you can find a good bed factory that fits your needs. You will know your supplier can make good beds and help your business grow.

You should always start by requesting samples before you place a large order. Samples let you see the real product and check if it matches your needs. You can touch the materials, test the strength, and look at the finish. This step helps you spot any problems early. Many buyers skip this step and face issues later.

When you request samples, ask the supplier to send the exact model you want. Make sure the sample uses the same materials and parts as the final product. If you need special features, tell the supplier before they make the sample. You can also ask for a sample with your logo or packaging. This helps you see how your brand will look.

Tip: Always check the sample for rough edges, loose screws, or weak joints. These signs show poor craftsmanship.

You should compare samples from different suppliers. This makes it easier to verify the quality of bed frames and choose the best option. If a supplier refuses to send a sample, you should be careful. Reliable manufacturers want you to trust their products.

Product photos give you a quick way to check the look and build of the beds. You should ask for clear, high-resolution photos from the supplier. Good photos show the bed from different angles. You can see the frame, joints, and any special features.

Ask for close-up shots of the corners, welds, and fittings. These details help you spot any weak points or poor work. You can also request photos of the beds in the factory. This shows you the real production process and not just a staged photo.

Some suppliers use computer images or old photos. Always ask for recent photos of the actual product. You can compare these photos with the sample you receive. This step helps you verify the quality of bed frames before you place a big order.

Note: If the photos look too perfect or do not match the sample, ask more questions. Honest suppliers will show you real photos.

Quality control is the backbone of any good manufacturing process. You should ask the supplier about their quality checks at every stage. A strong quality control system means fewer defects and better products. You can request a copy of their quality control plan. This plan should cover raw materials, assembly, and final inspection.

Factories with experienced quality staff produce better results. A study on Chinese manufacturers found that companies with skilled quality teams have fewer defects and pass more inspections. When staff have worked longer in quality roles, the beds are safer and stronger. On the other hand, factories with money problems often cut corners. This leads to more mistakes and lower quality.

You should ask who checks the beds and how often they do it. Some factories use outside inspectors for extra checks. You can also ask for reports from past inspections. These reports show if the factory meets safety and quality standards.

Ask about the training of quality staff.

Request inspection records for similar products.

Check if the factory uses third-party inspectors.

Tip: Good quality control protects your business and your customers. It also helps you avoid costly returns or complaints.

When you focus on quality control, you make sure every bed meets your standards. This step gives you peace of mind and helps your business grow.

You want to make sure your beds meet high standards before you ship them. One of the best ways to do this is by conducting third-party inspections. A third-party inspection means you hire an independent company to check the beds at the factory. This company does not work for you or the manufacturer. It gives you an honest report about the beds.

Why should you use a third-party inspection?

You get an unbiased view of the product quality.

You can spot problems before the beds leave the factory.

You save money by avoiding returns or unhappy customers.

You build trust with your buyers by showing them inspection reports.

Tip: Always choose a well-known inspection company. Some popular names are SGS, TÜV, and Intertek. These companies have strict rules and trained staff.

How does a third-party inspection work?

You book the inspection before the beds ship.

The inspector visits the factory and checks the beds.

The inspector looks at the materials, size, finish, and safety.

The inspector tests the beds for strength and stability.

You get a detailed report with photos and results.

Here is a simple table showing what inspectors usually check:

Inspection Item | What Inspectors Do | Why It Matters |

|---|---|---|

Materials | Check wood, metal, or MDF | Ensures correct materials |

Workmanship | Look for rough edges, joints | Finds weak spots |

Size and Shape | Measure all parts | Beds fit your needs |

Safety Features | Test for sharp points | Keeps users safe |

Load Test | Add weight to the bed | Checks strength |

You should ask for the inspection report before you pay the final balance. Read the report carefully. Look at the photos and test results. If you see any problems, talk to the manufacturer right away. Good suppliers will fix issues before shipping.

Note: Some buyers ask for random checks during production. This helps you catch problems early, not just at the end.

When you verify the quality of bed frames, third-party inspection gives you peace of mind. You know the beds meet your standards and your customers will be happy. This step is very important if you order large quantities or sell to strict markets like the UK or Europe.

By conducting third-party inspections, you protect your business and your reputation. You also show your buyers that you care about quality and safety.

When you choose a Chinese bed manufacturer, you should look at the size of their factory. Factory size tells you how much space the company has for machines, workers, and storage. A large factory often means the company can handle big orders and has more advanced equipment. You can ask the supplier for details about their factory area in square metres. Some factories also share videos or photos of their workshops.

You should check if the factory has separate areas for cutting, assembling, painting, and packing. This setup helps keep the work organised and clean. A well-organised factory often produces better beds. You can also ask how many workers they have. More workers usually mean faster production, but you should also look at the skill level. Good factories invest in training to improve craftsmanship.

Tip: Ask for a factory layout or a short video tour. This helps you see how the company manages its space and work.

Capacity means how many beds the factory can make in a month or year. You need to know this number to make sure the supplier can meet your order size. Some factories can make thousands of beds each month, while others focus on smaller, custom orders. You should ask for clear numbers and examples of past orders.

You can use a table to compare the capacity of different suppliers:

Supplier Name | Monthly Capacity | Main Bed Types |

|---|---|---|

Supplier X | 5,000 units | Metal, Bunk |

Supplier Y | 2,000 units | Solid Wood |

Supplier Z | 10,000 units | MDF, Metal |

If you plan to grow your business, choose a supplier with enough capacity for future orders. Factories in manufacturing hubs like foshan often have higher capacity and better supply chains. This location gives you more options and faster service.

Lead time is the number of days or weeks the factory needs to finish your order. You should always ask for a clear lead time before you sign a contract. Lead times can change based on the season, order size, and how busy the factory is. Most factories need 30 to 60 days for standard orders. Custom designs may take longer.

You should ask the supplier how they manage their schedule. Good factories give you updates during production. If you need beds quickly, check if the factory can speed up the process for urgent orders. Always add extra time for shipping and customs checks.

Note: Clear lead times help you plan your sales and avoid delays for your customers.

When you work with a Chinese bed manufacturer, you can ask for custom solutions. Customisation helps you stand out in your market. You can offer beds that match your brand, fit special spaces, or meet unique customer needs.

What can you customise?

Bed size: You can ask for non-standard sizes, such as extra-long or extra-wide beds.

Materials: Choose from solid wood, metal, or eco-friendly options.

Colours and finishes: Pick colours that match your brand or project.

Design features: Add storage drawers, headboards, or safety rails.

Branding: Request your logo on the bed frame or packaging.

Packaging: Ask for special packaging to protect beds during shipping.

Tip: Make a list of all the features you want before you talk to the manufacturer. This helps you explain your needs clearly.

How do you get custom solutions?

Share your ideas: Send drawings, photos, or sketches to show what you want.

Discuss details: Talk about sizes, materials, and finishes. Ask questions if you are not sure.

Request a prototype: Ask the factory to make one sample first. Check the sample for quality and design.

Give feedback: Tell the supplier what you like or want to change. Good manufacturers will adjust the design.

Confirm the final design: Approve the sample before you order in bulk.

Here is a simple table to help you compare custom options:

Custom Option | What to Ask For | Why It Matters |

|---|---|---|

Size | Exact measurements | Fits your space or market |

Material | Wood, metal, eco-friendly | Matches your quality goals |

Colour/Finish | Paint, stain, powder-coating | Matches your brand style |

Extra Features | Drawers, rails, headboards | Adds value for customers |

Branding | Logo on frame or packaging | Builds your brand identity |

Note: Always check if the factory has experience with custom orders. Ask for photos of past custom projects.

Custom solutions may take more time and cost more than standard beds. You should ask about the lead time and price before you start. Clear communication helps you avoid mistakes. Use simple words and pictures to explain your ideas. If you can, visit the factory or use video calls to see the progress.

When you choose custom solutions, you can offer beds that no one else has. This helps you win more customers and grow your business.

You should always look at reviews before picking a Chinese bed manufacturer. Reviews show what other buyers think. Many people write reviews on trade sites or business directories. These comments tell you about quality, delivery, and service. Some reviews talk about good things, while others mention problems. Honest reviews help you see both sides. Some buyers write about how the company fixes issues or delays. Others share if the beds are good after they arrive. If you see lots of good reviews, you can feel safer choosing that supplier.

Tip: Try to read reviews from buyers in your country. Their stories might be most helpful for you.

You should ask the manufacturer for client references. A good supplier will give you names or contacts of old customers. You can talk to these people and ask about their experience. This helps you get real feedback about the supplier. When you speak to a reference, ask easy questions. Did the supplier send the beds on time? Was the quality as promised? Did the company fix any problems well? Honest answers from real clients help you know what to expect.

Make a list of questions before you call or email.

Write down what each client says.

Compare answers from different clients to see if there are patterns.

Client references help you avoid surprises. You can use this information to make a better choice.

Awards show that a manufacturer is special in the industry. Some Chinese bed manufacturers have won big awards for their work. For example, Rongshun Medical got two important health awards in China in 2011. The company received the “Healthy China 2011 Public Health Brand Enterprise” and the “Healthy China 2011 Outstanding Contribution Award for Healthcare Industry.” People’s Daily, a respected group, gave these awards. These honours show the company helped public health and the healthcare industry.

When you see a manufacturer with awards, you know they worked hard for a good name. Awards can also mean the company has high standards and cares about quality. You should ask suppliers if they have won any awards or industry honours. This can help you pick a partner who wants to do their best.

Talking well with your Chinese bed manufacturer helps you work together better. You need to talk clearly so there are no mistakes or late orders. When picking a supplier, see how well they talk with you.

Why is communication important?

You get answers fast when you ask questions.

You know what is happening with your order.

You can fix small problems before they get big.

You feel sure about your order and the supplier.

A good supplier will answer your emails or messages in one day. If they reply fast, it means they care about your business. If they take too long, your order might be late.

Tip: Try sending some questions before you order. See how quickly and clearly they reply.

Check if the supplier really understands what you want. Sometimes, language can make things hard to understand. Use easy words and short sentences. Ask the supplier to repeat your requests in their own words. This way, you know they understand you.

Here is a table to help you see if the supplier is good at talking:

What to Check | Good Sign | Warning Sign |

|---|---|---|

Response Time | Replies in 24 hours | Takes days to reply |

Clarity | Gives clear, simple answers | Answers are confusing |

Language Skills | Understands your questions | Often misunderstands |

Updates | Sends regular progress reports | No updates unless you ask |

Problem Solving | Offers solutions quickly | Avoids or ignores problems |

Ask the supplier to send you updates while they make your beds. Good suppliers send photos or videos to show how things are going. These updates help you see if there are any problems early.

Note: Use email, instant messages, or video calls to talk. Video calls let you see the factory and talk face-to-face.

If you want something special, write it down clearly. You can use pictures or drawings to show your ideas. Ask the supplier to write back and confirm every detail. This helps stop mistakes.

Good talking builds trust between you and the supplier. You feel safe when you know what is happening. It is also easier to fix problems if you talk well. Always pick a supplier who likes clear and honest talks.

A factory visit gives you a real look at how your beds are made. You see the machines, the workers, and the quality of the products. You can check if the factory matches what the supplier told you online. This step helps you avoid scams and low-quality suppliers.

When you visit, walk through the production lines. Watch how workers handle materials and assemble the beds. Look for clean workspaces and organised tools. A tidy factory often means better quality control. You should also check the storage area. Beds and materials should be stored safely and neatly.

Ask to see the quality control process. You can request to watch an inspection or see finished products. Take notes and photos if the supplier allows it. This helps you remember details when you compare factories later.

Tip: Bring a checklist with you. Write down what you want to see, such as certificates on the wall, safety signs, and staff uniforms.

Here is a simple checklist for your visit:

Company licence and certificates on display

Clean and safe work areas

Skilled workers at each station

Quality control checks in progress

Proper storage of materials and finished beds

Clear labelling and packaging

If you cannot visit in person, you can hire a third-party agent. Many companies in China offer factory audit services. They send you a report with photos and comments.

After you finish your factory visit, you need to talk about the business terms. Good negotiation helps you get better prices, payment rules, and delivery times. You should prepare before you start.

Start by knowing your target price and the highest price you can accept. Ask the supplier for a detailed quote. The quote should list the price per bed, the minimum order quantity, lead time, and payment terms.

You can use a table to compare offers from different suppliers:

Supplier | Price per Bed | MOQ | Lead Time | Payment Terms |

|---|---|---|---|---|

A | £80 | 100 | 40 days | 30/70 |

B | £75 | 200 | 35 days | 50/50 |

C | £85 | 150 | 30 days | 30/70 |

Note: “30/70” means you pay 30% as a deposit and 70% after the beds are ready.

Ask about discounts for larger orders or repeat business. You can also discuss who pays for shipping and insurance. Make sure you agree on how to handle defects or delays.

Always get the final agreement in writing. Both you and the supplier should sign the contract. This protects you if problems happen later.

Tip: Stay polite and clear during talks. Good communication helps you build a strong business relationship.

You can find the best Chinese bed manufacturer by using simple steps. Always look at their credentials and check the quality of their beds. This helps you trust them and stops you from making mistakes. When you check these things, you get:

Safe and useful information

Quicker and better checks

Fewer problems and better results

Aspect | Step-by-Step Choice | Random Choice |

|---|---|---|

Efficiency | High | Lower |

Cost | Lower | Higher |

Reliability | Strong in same settings | Changes |

If you follow these steps, you are more likely to work well with your supplier and get beds that fit what you want.

Most orders take about 30 to 60 days to finish. If you want a custom bed, it might take longer. Always ask your supplier how long your order will take before you buy.

Ask the supplier for their business licence and certificates. You can look up their company details on official websites. Good suppliers will give you this information and reply to your questions quickly.

Yes, most manufacturers can make custom beds for you. You can ask for special sizes, different materials, colours, or your own logo. Tell them your ideas and ask for a sample before you order a lot.

Most suppliers want a deposit, usually 30%, before they start making your beds. You pay the rest after they check the beds or before they send them. Always write down your payment rules so both sides agree.

Yes, you can go to the factory to see how beds are made. A visit lets you check the work and quality. If you cannot go, you can pay a third-party agent to check the factory for you.

Look for BSCI, FSC, ISO 9001, and CE certificates. These show the factory follows rules for quality, safety, and fair work. Always ask for copies and check if the certificates are real.

Tell your supplier right away if there is a problem. Send photos and explain what is wrong. Good suppliers will help you by sending new beds or giving your money back. Always keep messages and records of your talks.

It is safe if you pick trusted suppliers online. Use well-known websites, read reviews, and ask for samples. Never pay all the money before you get and check your beds.